Pushing the limits of detector technology

Metal detectors have come a long way since they were first used for mine, mineral and treasure detection early last century, early mine detectors that were being used in WWII would of been hard pushed to detect something the size of a ten cent piece but mines back then were the size of dinner plates and full metal construction.

Mines these days have no metal components that detectable due to using very thin and fine wires and metal components that do not give off much reaction to external electromagnetic field such as from metal detectors.

New technology has moved towards ground penetrating radar and infrared imaging, nuclear quadrupole resonance, x-ray backscatter and a host of other newer techniques. All these have drawbacks in certain soil or ground types and non have found their way into consumer detection equipment aimed at the gold market that work in highly mineralised ground.

A few years ago I had a fellow come to see me with some equipment that he purchased overseas and he was told it would find gold nuggets. He had some trouble and said to me that he could not get the equipment to work. I inspected the equipment and found it could not detect a 10 ounce nugget that I buried in garden soil only six inches deep. It was some type of ground penetrating radar type unit and the fellow paid out $95,000 for two units. I also had an electronic engineer who specialises in this type of equipment take a look and at the end of the day we were in agreement that the units just did not work.

It is similar to these so called long rang locators that are advertised for finding gold and treasure, these things do not work at all. Some years ago some people that I know had one of these long range locator “salesmen” carry out a demonstration for them, at the demo site a six ounce nugget was placed at the base of a tree and covered with leaves, the fellow doing the demo was standing three meters from the nugget but the long range locator was indicating gold was five kilometres in some direction. When the nugget was produced and the salesman asked why his locator did not detect it he came up with the excuse it was from interference. Please do not be conned by these people, these things do not work.

To date it seems like the only viable technology for finding gold in the goldfields is by use of electromagnetic means, that is a coil and electronic control box. We are really pushing the limits of this technology and in all fairness not much has changed in over thirty years. Detectors can be looked at the same way as motor cars, they are all much the same but some have refinements that make the usage easier but at the end of the day they all get you from point A to point B. Detectors are fairly basic in operational theory, use a small coil and get small gold, use a larger coil and get bigger targets deeper. I hear about people sifting dirt for ten minutes to get there 0.05 gram bit, $2 worth of gold with these newer expensive detectors but get an old detector and install a 6” or 8” coil on it and the results may surprise you. So many times I see detectorists using huge coils and complain that they found nothing but their mate using a detector with an 8” coil found half a dozen bits. As most of the gold in the gold fields is small what do people expect?

Small gold is very hard to detect and even the most insensitive detector can be made to respond to small gold just by getting the detector to transmit faster narrower pulses and turn on the receiver faster as long as the ground subtraction circuitry is up to the task.

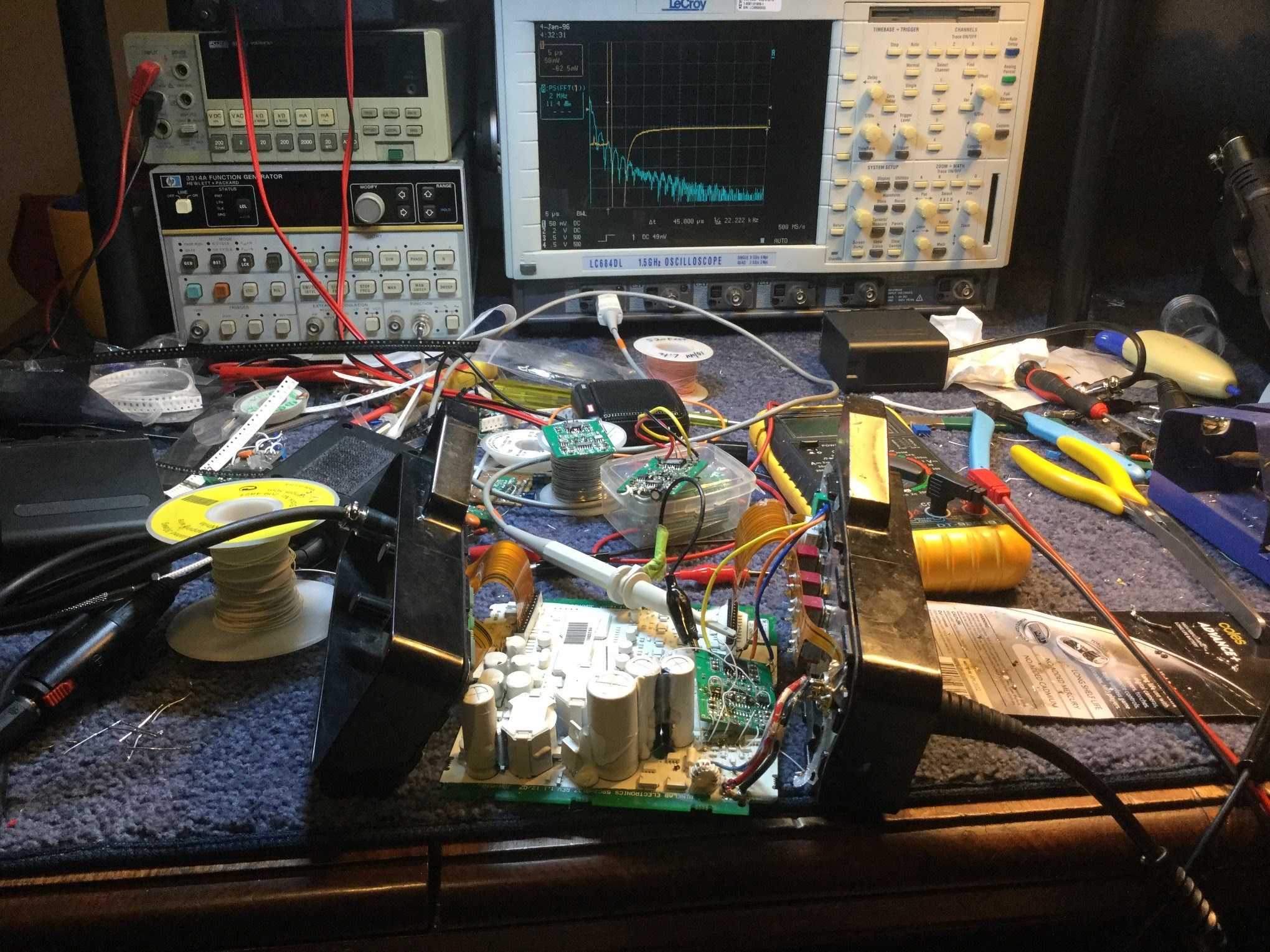

So what can be done to make the best of the best to make them even better at finding gold. Most detector designs take around three years from concept to being available to the public and sometimes it can be longer. Trying to push a new design out the door too quickly has also resulted in product recalls and even design defects that the manufacturers hope never cause problems until the warranty runs out. The electronics industry is always bringing out newer components and thus a product that is entering the market is already three years behind the times. This is why every detector that is out and about can be made better with lower noise and more efficient components, faster and greater resolution in processor power, more resolution in better analogue to digital converter IC chips. There are gains to be had across the spectrum of components. There is still a lot to be done with coil design, lower capacitance windings and getting rid of the coil cable, this can be replaced with a low noise preamplifier and fed back into the detector via a fibre optic cable in order to reduce cable capacitance, obviously the transmitter needs a copper cable but the receiver does not. Lower capacitance input components, fixed setting converted into variable settings and general component upgrades can make a substantial difference. I have been playing around with a new type of coil that if I ever get around to manufacture it will massively improve the performance of older detectors, there are ways of removing all the external interference and not lose any performance at all, actually there is a huge performance boost.

The problem being a one or two man show is having the resources available to get all these projects off the drawing board and into the market, it takes a lot of time, money and energy to make things happen. Just thinking that seven years ago I purchased a fully automatic vacuum forming machine for making coils and to date I think that we have produced only twelve test coils. The poor vacuum forming machine is sitting in a factory gathering dust. It is very frustrating to have the technology but not the time to manufacture products for the metal detecting market.